Guarantee time: 2 years

Applications

Control of centrifuges, ovens, presses, food processing, packaging machines, cleaning systems, washing machines, wood refining machines, compressors, scales, office machines, power converters, heating, cooling, testing and measuring devices with two thermo-couples and/or two resistance thermometers (RTDs) etc. The micro-controller ET-OLED is especially suitable for series production of price sensitive products that require accurate and fast temperature measurements and control, control of frequency converters or servodrives over Modbus, analog or digital outputs.

Advantages

1. Compactness

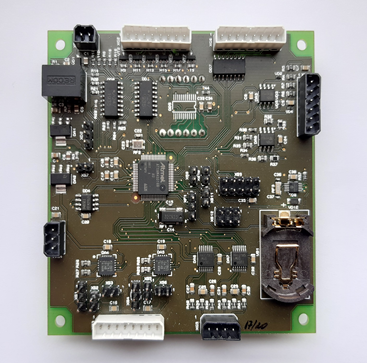

ET-OLED is suitable for smaller or portable machinery where a compact solution is necessary. The micro-controller ET-OLED (size 86 x 86 x 20 mm) can be a substitute for several PLC modules while still retaining all the required functionality at a fraction of the size.

2. Cost effectiveness

ET-OLED is suitable for smaller or portable machinery where a compact solution is necessary. The ET-OLED (size 86 x 86 x 20 mm) can be a substitute for several PLC modules while still retaining all the required functionality at a fraction of the size.

3. Tailored for your application

The hard- and software of ET-OLED will be tailored according to your requirements. The front panel sticker can be designed according to your wishes. ET-OLED is available also in 96×96 mm DIN enclosure to reduce assembly costs.

Features

| Micro-controller | Atmel 32-bit with powerful features fully accessible |

| Programming language | freely programmable in C language |

| Memory | FLASH memory for permanently saving user settings and parameters during operation. Default settings can be restored if necessary. Part of RAM is buffered by lithium battery on board. The process can continue after power outage. |

| Display | clear green graphic 128 x 64 pixel OLED screen with adjustable brightness |

| Keyboard | 4 buttons on board or sticker keyboard with buttons or rotary encoder for easier setup |

| Audio | programmable sound signals to indicate faults or operation status |

| Clock-calendar | real time clock-calendar with lithium battery backup allow to continue timely control in spite of possible power outages |

| Programming interface | JTAG and serial port for PC connection for programming/debugging and logging |

| Data connection | RS485 Modbus for data exchange with master or slave device as frequency converter; SPI expansion pins for an extension board |

| Connectors | removable spring connectors for fast and reliable installation and removal |

| Supply voltage | 24 VDC +25% -30% |

| Digital inputs | 6, 24 VDC optically isolated |

| Digital outputs | 6, 500 mA, optically isolated 1 kV, including 4 PWM outputs (can be configured) |

| Analogue inputs | 2 (0 – 10 V) |

| Analogue outputs | 2 (0 – 10 V) |

| Protection | panel mount with sticker front panel: IPX5; backside IP00; DIN 96×96 enclosure |

| Operating temperature: | -40oC…+70 oC (battery discharge -20 oC…+70 oC) |

| Humidity: | no condensation; conformal coating available on request |

3. Tailored for your application

- Display of temperatures from all thermocouple and RTD inputs.

- Temperature controller configurable from the screen with transistor output to electromagnetic or solid state relays.

- Modbus master to control slave devices like HMIs, variable frequency drives and other.

- Multiple configurable inputs and outputs to suit all requirements.

- The micro-controller can be programmed according to your requirements.

- The buzzer can be programmed to indicate faults or important steps in the program.

- Four button interface is simple and easy to learn. A single rotary switch version is available with an even more intuitive and faster navigation within menus